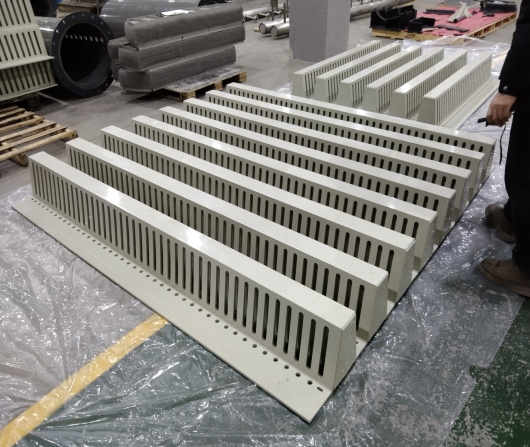

填料塔和填料柱的塑料驼峰支撑

塑料 驼峰支撑 (也称为 填料支撑格栅 或者 床位限制器) 是 填料塔 和 蒸馏塔,旨在均匀分布重量并防止填料(例如鲍尔环、拉西环或结构填料)塌陷或堵塞塔的下部。塑料驼峰支撑的主要特点材料: 由...制成 PP(聚丙烯)、PVDF(聚偏氟乙烯)或 CPVC,因其耐化学性而被选中。设计: 波浪状(驼峰)或网格状结构,允许高 开放区域 (60-90%)最佳 流体流动.功能:支持 填料重量 以防止破损。确保 均匀的气体和液体分布.防止填料落入塔的下部。耐腐蚀性: 适合 酸性、碱性和有机化学品 环境。重量轻且易于安装: 在腐蚀条件下比金属支架更耐用。应用1. 化学和石化工业蒸馏、吸收和洗涤塔用于:硫酸、硝酸和盐酸工艺。气体处理(H₂S、CO₂ 去除)。制药和农用化学品行业的溶剂回收。2. 水和废水处理洗涤塔 用于移除 氨、氯和挥发性有机化合物.冷却塔 包装支持最大化 传热效率.3. 空气污染控制用于 烟气脱硫(FGD)系统 持有 随机填料.除臭洗涤器 针对工业排放。4.石油和天然气工业乙二醇脱水塔 (天然气加工)。胺脱硫装置 (去除 H₂S 和 CO₂)。

阅读更多